The key to improve the efficiency of industrial production

Differential pressure transmitter

As an important industrial measuring equipment, differential pressure transmitter is getting more and more attention. Its accuracy and stability have a non-negligible role in improving industrial production efficiency. This paper will introduce the basic concept, working principle and application in industrial production of differential pressure transmitter in detail.

First, a differential pressure transmitter is a device that outputs an electrical signal by measuring the differential pressure between two or more pressure points. It is mainly composed of three parts: sensor, measuring element and converter. The sensor is responsible for receiving the differential pressure signal from the bilateral pressure guide tube, the measuring element converts the differential pressure signal into an electrical signal, and finally the electrical signal is processed by the converter into a standard electrical signal output.

In practical applications, differential pressure transmitters are widely used in various industrial fields. For example, it can be used in the power industry to control the combustion process by monitoring the differential pressure of boilers or steam pipelines, ensuring the full utilization of energy. In the chemical industry, differential pressure transmitters can be used to monitor the conditions of various chemical reactions to ensure production efficiency and product quality. In water conservancy projects, differential pressure transmitters can be used to monitor the water level of DAMS or reservoirs to provide data support for flood prevention.

In order to better use the differential pressure transmitter, the following points are worth learning from. First of all, choosing the right differential pressure transmitter is the key. Different types of transmitters are suitable for different pressure ranges and measurement accuracy, and need to be selected according to actual needs. Secondly, the correct installation and debugging is also an important part of ensuring the normal operation of the differential pressure transmitter. This includes installation in accordance with the requirements in the instructions and commissioning as necessary to ensure the accuracy of the measurement results. Finally, routine maintenance and overhaul are equally important. Regular inspection of the operating status of the equipment, timely discovery and solution of problems, help to extend the service life of the equipment.

In short, differential pressure transmitter as a key equipment to improve industrial production efficiency, its importance is self-evident. In the future, with the continuous improvement of measurement accuracy and stability requirements in the industrial field, the application prospect of differential pressure transmitters will be broader. Let us look forward to further developments in this area.

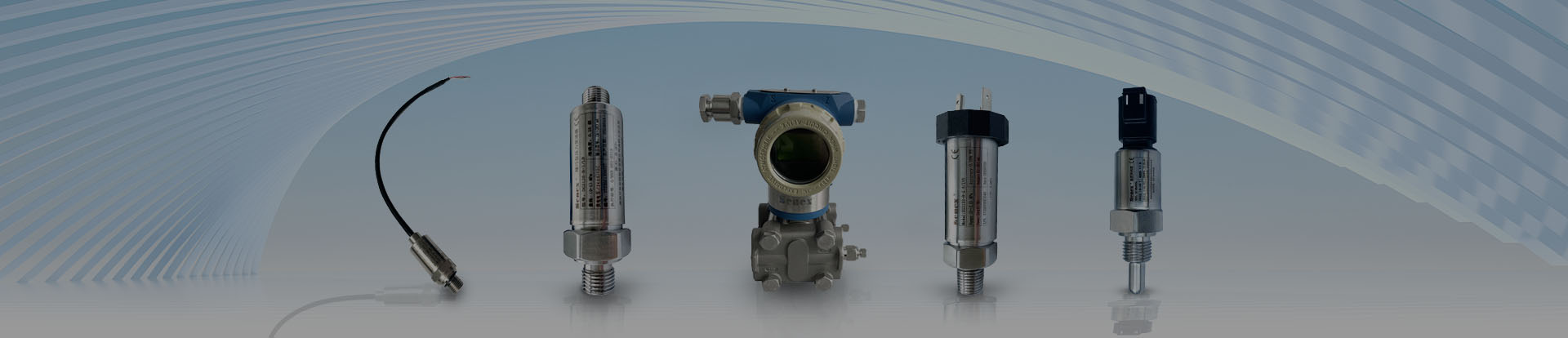

Related products

Post time: Sep-22-2023