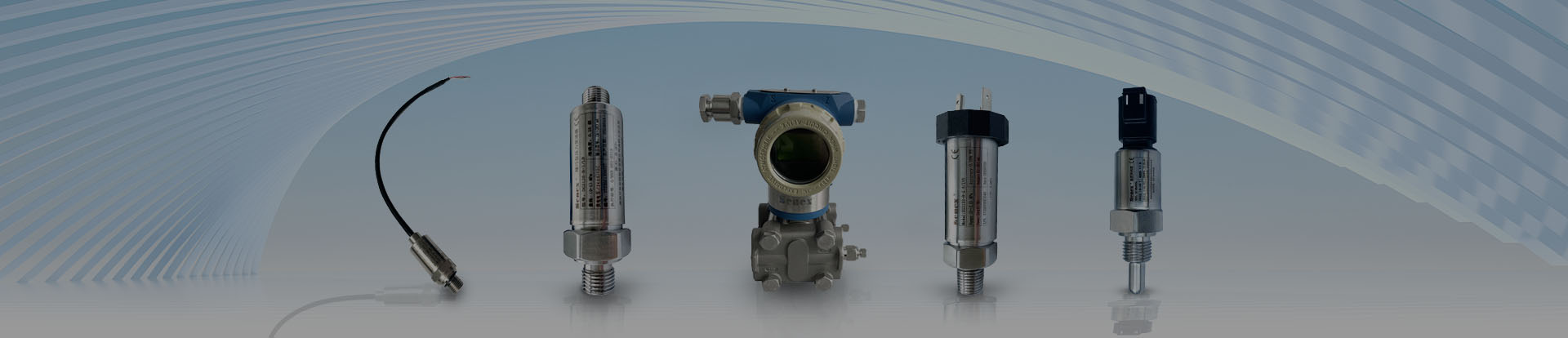

NT Series Pressure Sensor Core

With the best-in-class accuracy, NT series pressure sensor core features the wide range of ports, connectors, and analog electrical outputs for ease of integration in various industrial applications.

1. Using 17-4PH stainless steel material and two pieces of MEMS silicon wafers.

2. Stable performance, high tolerance, service life ≥ 10 million times.

3. Stainless steel integrated structure, no welding seam, no silicon oil filling, no leakage hidden danger.

4. Safe structure, automated process, easy mass production, high sensitivity output, low power consumption.

5. It can meet customized requirements, such as front-end pressure port, rear-end thread, sealing method...

| Requirements | Spec | Units | Remarks |

| Offset error | 0±2 | Mv(DC5V) | |

| Span error | 16±4 | mV/V | |

| Linearity | 0.25 | %Span(BFSL) | |

| Pressure Hysteresis | ±0.1 | %Span | |

| Pressure Repeatability | ±0.1 | %Span | |

| TCO | 0.03 | %FS/℃ | |

| TCS | 0.05 | %FS/℃ | |

| Long Term Stability | 0.25 | %Span(25℃) | |

| Insulation Resistance | 100 | MΩ | |

| Over Pressure | 2 | Rated | |

| Burst Pressure | 5 | Rated | |

| Life | 10 | Million | 10-90% FS |

| Operation Temperature | -40~125 | ℃ | |

| Storage Temperature | -40~125 | ℃ | |

| Mechanical Vibration | 50 | g | 10Hz~2kHz |

| Mechanical Shock | 100 | g | |

| Wetted material | 17-4PH Stainless Steel | ||

| ROHS | √ | ||

| Customization | √ | ||

Write your message here and send it to us